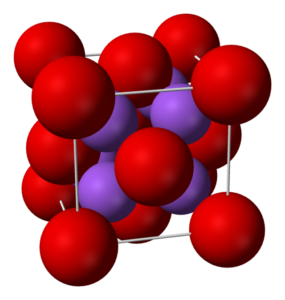

- Strong alkaline flux

- Low toxicity

- Creates brightly colored glazes

- Exact melting point is 1652°F

- Begins melting at around 1580°F

- Best to begin to reduce high-sodium glazes at this point

- Powerful flux at all temperatures

- Often seen written as KNaO

- Similar to potassium oxide (K2O) in color response and expansion and contraction rate.

- Often insoluble sources include

- Some potassium oxide; ie: feldspar, which are the primary source of sodium in high-fire glazes

- Usually contain varying amounts of both sodium and potassium oxides

- Some potassium oxide; ie: feldspar, which are the primary source of sodium in high-fire glazes

- Most sources are soluble and can act as deflocculants in a glaze slurry or casting slip

- Glazes such as copper red or carbon trap shines, which have soluble sources of sodium oxide like soda ash, borax, or nepheline syenite, can easily become deflocculated.

- An interesting characteristic is that it’s volatile above 2012°F and will cause flashing on clay body as it leaves glaze

- Due to this effect it’s widely used in vapor glazing techniques like soda and salt firings

- Exhibits low viscosity and surface tension

- If used in high enough quantities it will cause glazes to run

- Has high expansion and contraction rate and will often cause crazing in glazes

- Creates soft glaze surfaces that are easily abraded by cutlery, acids, and bases (detergents).

- Insoluble source include sodium feldspars, Minspar, Kona F-4, NC-4, Bainbridge, Eureka, Godfrey, and cryolite.

- Also present in potash feldspars

- Including Custer, G-200, K-200, Plastic Vitrox, Cornwall Stone, volcanic ash, and rottenstone

- Soluble forms include soda ash, baking soda, salt, borax, unwashed woods, Gerstley Borate and its substitutes, and sodium silicate

- Nepheline syenite and Frits are slight soluble